RecommendMail Facebook LinkedIn

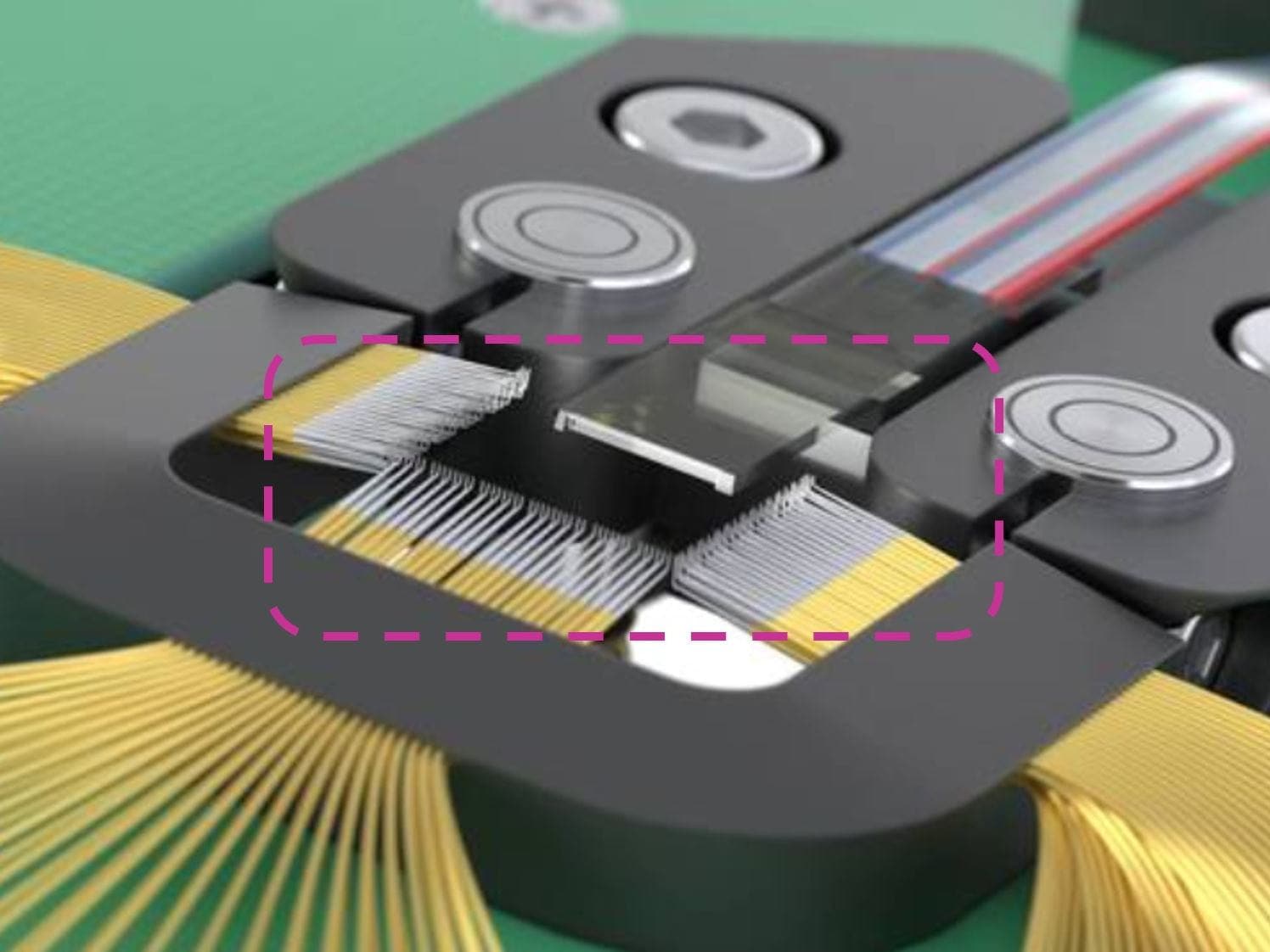

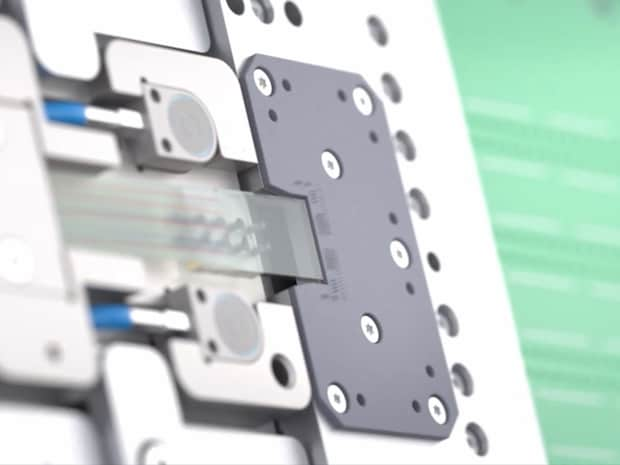

UFO Probe® Card for PIC testing

Using the UFO Probe® Card for testing Photonic Integrated Circuits (PICs) – the chips of the future.

Speed up the world

UFO Probe® Technology keeps you one step ahead

Built-in solution for high-volume production

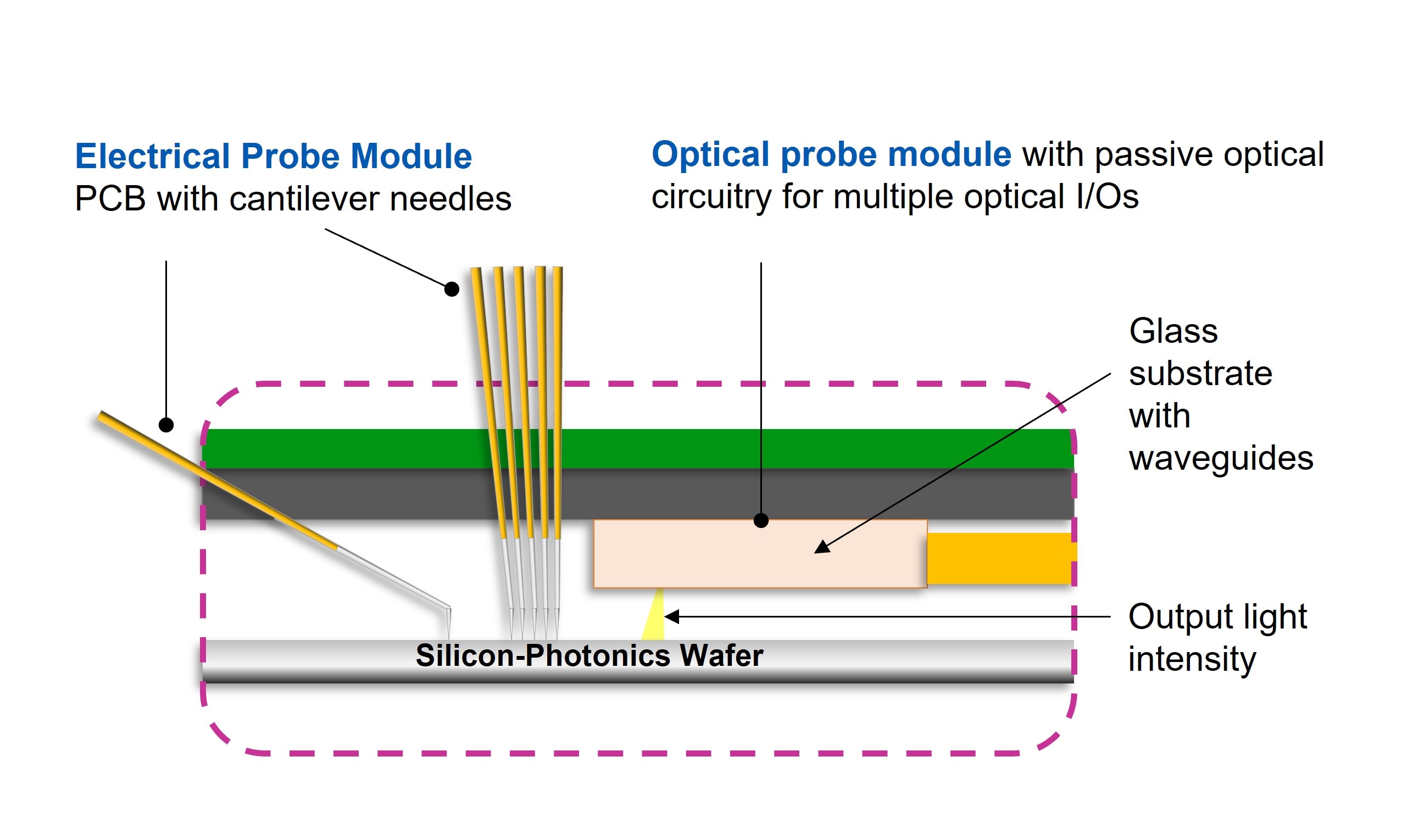

New Jenoptik UFO Probe® Vertical

As the Cantilever Version, the UFO Probe® Vertical enables parallel functional tests of optical as well as electrical components on chips using vertical needle technology from MPI. This allows the user to couple up to 32 optical channels in parallel as standard - or more if required - without the need for active alignment.

Opto-electronics tests with high throughputs:

- Covers wavelength range from 1260 to 1625 nm used in the telecom and datacom sector

- Ability to provide polarization maintaining for individual or all optical channels

- Testing of bond pads, solder bumps or copper pillars

- Contacts up to tens of thousands of bond pads with dimensions down to 35µm.

- Smallest addressable pitch of electrical contacts from 40 to 80 µm

- Vertical probes with lower and more uniform contact resistance from 0.2 to 1.0 ohms, depending on the probe type, while minimizing probe marks.

- Ensure economical use in high-volume test scenarios and ATE operability.

All benefits of the Probe Card Technology on one view

Progress

Being ahead: The innovative 2-in-1 test solution expands the PIC ecosystem and enables high-volume production of high-performance chips.

Innovation

For the first time: Combines an optical and an electrical test module in just one probe card for parallel qualification – without the need for active alignment.

Quality

Identify known-good-dies: Have complete information about the functionalities of PICs in early stage of wafer production to reduce costs in the following production steps.

Integration

Use what is there: Probe card operates on existing standard IC wafer probers or test equipment.

Efficiency

Reduced test time: The alignment step is only required once per wafer, not once per PIC.

Flexibility

One platform - many options: The UFO-Probe® is suitable for many applications and can be customized to meet your needs.

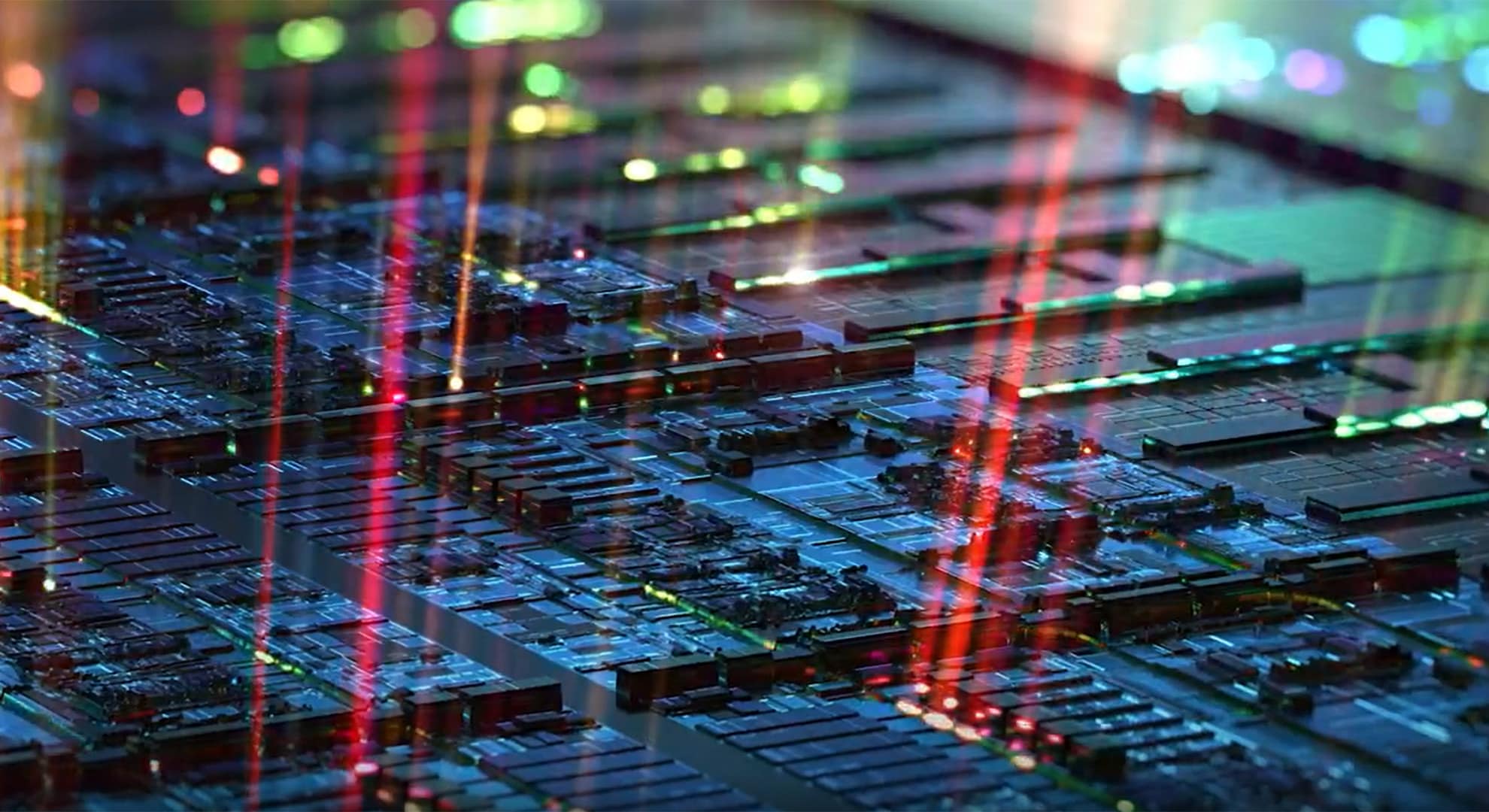

Enabling optical data communication

Probe card applications now and in the future

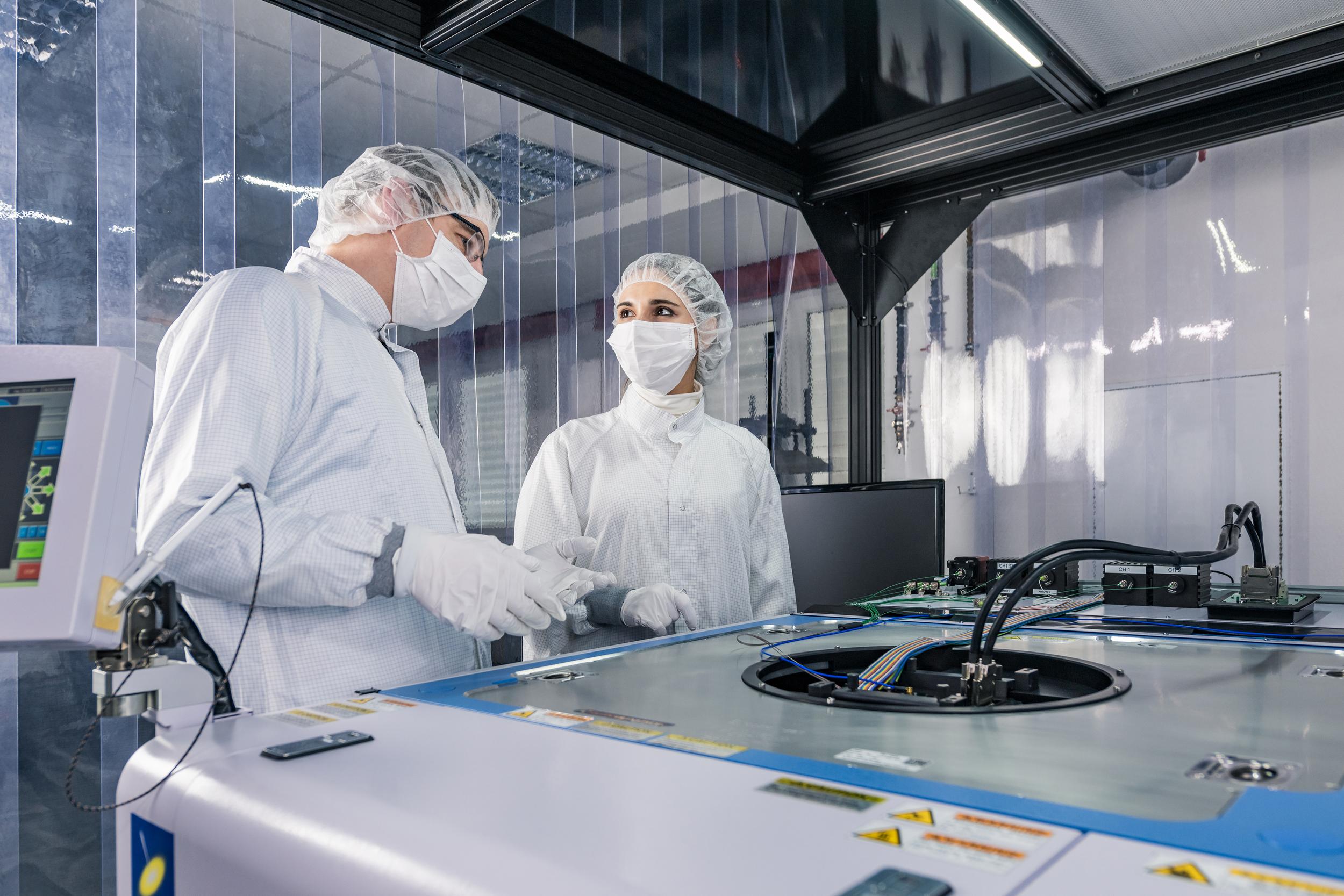

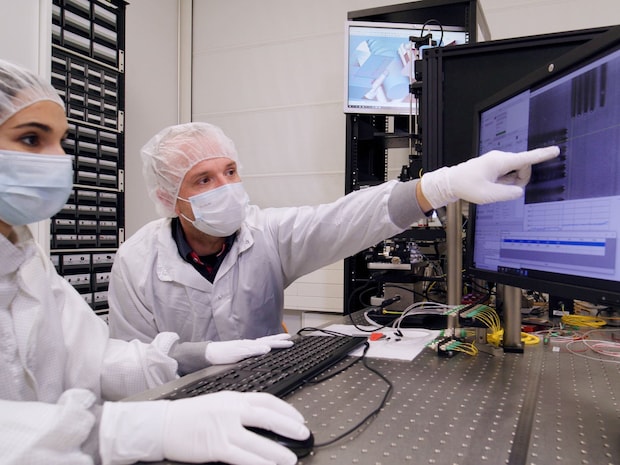

Easy integration into existing infrastructure

Whether you use a cantilever or vertical version of the UFO Probe® Card, it is intended to be used for operation on standard IC-probers and automated test equipment. So, Jenoptik offers a plug-and-play solution for PIC wafer-level tests. Depending on requirements, standard interfaces to wafer probers can be easily implemented in the design of the probe cards. The operation of these novel probe cards is similar to that of electrical ones, so existing personnel won't need extensive extra training.

Combination of novel optical concept and proven needle technology

- Monolithic optical module

- Alignment-insensitive optical coupling for vertically emitting PICs

- Simultaneous optical and electrical contacting

- Optical concept compensates prober alignment tolerances

- Use of proven needle technology (partnership with test card manufacturers)

- Standard interface to wafer prober

Technical details of the UFO Probe® Card

| Specifications | Current generation | Future generations |

|---|---|---|

Component to be tested | Electronic and photonic integrated circuit (EPIC); optical transceivers for data transmission and telecommunications applications | EPIC for transceivers, photodiodes, |

Electric needle technology | Cantilever and vertical | Cantilever, vertical/advanced |

Optical coupling principle DUT | Vertical coupling | Vertical coupling |

Number of optical inputs/outputs (OI/OO) | Up to 32 or more | <200 |

Pitch OI/OO | 127 μm, 250 μm, flexible for >250 μm | flexible |

Layout configuration of OI/OO arrays | Linear arrangement with same direction of inputs/outputs | Configurable to own needs |

Coupling angle | 0° and 11.6° standard, up to 20° customized | 0° - 20° |

Supported wavelength | 1260 - 1625 nm (O/ L-band) | VIS to NIR (U-band) |

Measurement of insertion loss | Repeatability: ~ 0.3 dB | Repeatability target: 0.1 dB |

RF measurement | Up to 110 GHz, depending on needle technology | GHz |

Interfaces | Eurocard format; ATE* | Eurocard format; |

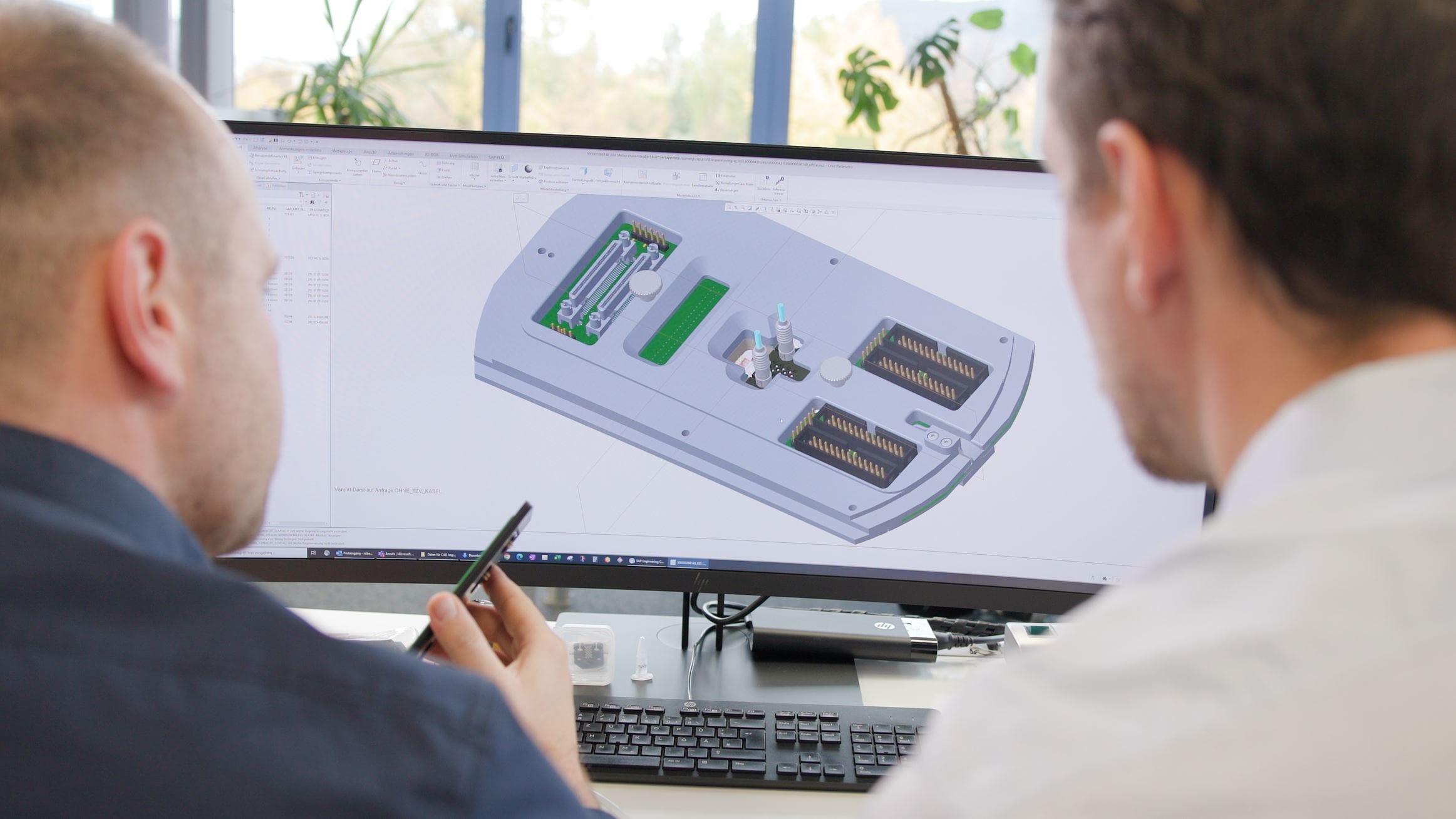

Customized Probe Card for your success

Based on the UFO Probe Technology, we will customize a specific opto-electronic test solution that will fit the complex demands of your application.

Each UFO Probe® Card is customized to the individual requirements and the respective wafer layout and is available with both cantilever and vertical needle technology. Check out the specifications for more details.

Your partner in PIC testing

Jenoptik has profound expertise and know-how in micro-optics and optics and we are a competent and valuable partner to the semiconductor industry for many years. We know and understand the challenges of our customers and combine these with our technical experience and knowledge to create innovative solutions, such as the UFO Probe®Card. The necessary skills and the continuous development of technologies is just one aspect that we pursue with one goal: Moving you forward.

High-Performance from A to Z – our competencies:

- Design: Optical module and general electrical and optical probe card card

- Manufacturing and supply chain management

- Micro-assembly and alignment of optical and electrical modules

- Optical test and verification in lab: customized test rig

- Test under manufacturing conditions: Accretech UF3000 Prober

Have a closer look to the UFO Probe® Vertical

Do you have any questions? Our experts are happy to help.

Awarded! Thuringia Innovation Award 2022 for UFO Probe® card

Jenoptik was awarded the Thuringia Innovation Award 2022 in the "Industry & Materials" category on November 30, 2022 in Weimar, Thuringia for its novel opto-electronic probe card for testing PIC wafers. Not quite 100 applications were received by STIFT Thüringen this year. Jenoptik convinced the expert jury with its well-thought-out approach to solving the increasing demand for photonic technologies in the electronics and semiconductor industry.