RecommendMail Facebook LinkedIn

- Health & Science

How Jenoptik can help mitigate the risks of the CFDA approval process for your biomedical devices

Working directly with your component suppliers, including Jenoptik, is one of the best ways to ensure a smooth CFDA/NMPA approval process for your biomedical device.

, Ingolf Reischel

When introducing a new biomedical device to a new market, the manufacturer is naturally going to worry about the associated risks. For example: Will our biomedical device get the certifications and approvals it needs?

Traditionally, one of the biggest areas of uncertainty has been the Chinese market. With 1.4 billion people who want to take advantage of healthcare advances while living in a rapidly growing economy, China should be an excellent place to sell the latest medical technology. In general, it is – but it also has a reputation for being a risky marketplace to get a foot in the door, due to exacting requirements and the possibility of regulatory delays.

Fortunately, today’s China presents fewer delays to entering the marketplace. The reorganization of China’s regulatory agency for medical devices, plus the growing harmonization of its approval processes with other international standards, means that medical equipment manufacturers have less to worry about. Plus, they can readily find answers to their questions.

The CFDA/NMPA requirements for medical devices

In 2018, China’s CFDA was reorganized as the National Medical Products Administration, or NMPA (but CFDA, which stands for China Food and Drug Administration, is still a widely recognized acronym). The agency divides medical devices into three classes (known as I, II, or III) based on the risk to the patient, and lower risk devices require less in the way of trials. For manufacturers of biomedical devices, virtually all such systems fall into the low- or medium-risk categories and they may fall into one of the exemptions granted to some of the equipment in the second of the three risk-based classes.

For Class II and Class III devices, the CFDA/NMPA requires applicants to submit product samples so that the agency can examine them at one of its certified national testing centers.

Because the Chinese regulatory process has changed several times in the last decade, however, manufacturers in China and other countries still have concerns about getting their products approved for sale in the world’s most populous nation. Will they need to submit a clinical evaluation report (CER) or organize a full clinical trial? Must they show that they have demonstrated good quality manufacturing practices? Some of the information floating around on the internet is out of date because of the changes in regulations, both in China and with other standards governing bodies.

What your manufacturing partner can do for your CFDA biomedical device approval

If you are constructing your biomedical device out of components from another manufacturing partner, you could have a great advantage. The component manufacturer already has vast quantities of technical information about the parts; ask them about their consultative power and experience with the various national certifying bodies.

Thus, if your component supplier gives you the information you need to fill out the CFDA/NMPA application materials, you have a lower risk of getting additional questions and requests for more data from the Chinese agency. This does not speed up the approval process itself – only the agency can do that – but it reduces the risk of costly delays.

More importantly, though, getting all the necessary information from your component manufacturer to get the CFDA/NMPA approval, together you will speed up the process for getting your biomedical device into the market. And that will give you an edge over your competitors.

The optimum time to start planning your CFDA/NMPA certification process with your component manufacturer is early in the product development sequence. Your supplier will work to protect its intellectual property and will give the certifying authority only the information it needs, nothing more.

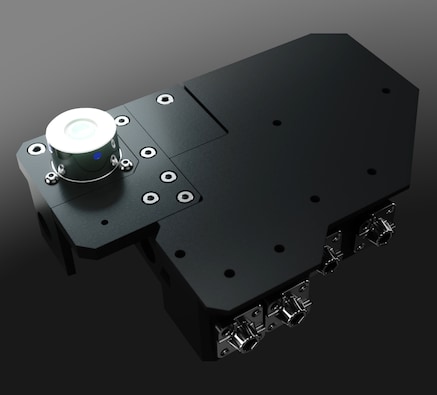

Suppose you are planning to upgrade your biomedical product to keep up with technological improvements. Must you start the CFDA/NMPA approval process all over again? Not necessarily. In certain cases, such as swapping out an image sensor for a new model with higher resolution, you can compare your product with a “predicate device.” You must demonstrate that your product is similar to the predicate device in terms of principle, structure, manufacturing materials, production processes, performance requirements, safety evaluation, alignment with national and industry standards of quality, and intended use. The predicate device must also have valid Chinese certification, which lasts for five years. Once again, your component manufacturer should be able to help supply information for this process. The JENOPTIK SYIONS® digital imaging platform, for example, designed for modular upgrading of your biomedical device, is compatible with these approval concepts.

Who knows what will happen with CFDA/NMPA regulations in future years? China has joined the International Medical Device Regulators Forum (IMDRF), a voluntary organization seeking “convergence” of standards for biomedical equipment. The European Union, Russia, Japan, and the United States also belong to the international forum. It is possible that China and the rest of the world could bring their standards even closer together, but it is also possible that they will diverge.

If you are interested in marketing and selling your biomedical device globally, talk to Jenoptik. We have been helping international companies like the leader in DNA sequencing and governmental scientific agencies to prepare their products for this world, as well as others.

Overall, working hand in hand with your trusted suppliers, such as Jenoptik, is the surest way to lessen the chance of regulatory delays and to smooth out the biomedical device regulatory processes in China as well as other countries.

You can rely on Jenoptik. Speak to us today.

Product Recommendations

About Ingolf Reischel

Especially in the field of medical technology, better and faster prevention, diagnosis and treatment of diseases are becoming increasingly important. As head of the market segment healthcare & life science, Ingolf Reischel technologically accompanies these topics in the division Light & Optics. A particular focus is on diagnostic, dental, ophthalmological and biotechnological applications. As an engineer in technology electronics and industry expert, he knows the interaction of optics, electronics and mechanics as well as the requirements for approval and quality assurance of medical technology systems in an international context.