Elevate solar cell manufacturing with Jenoptik’s high precision F-Theta lenses

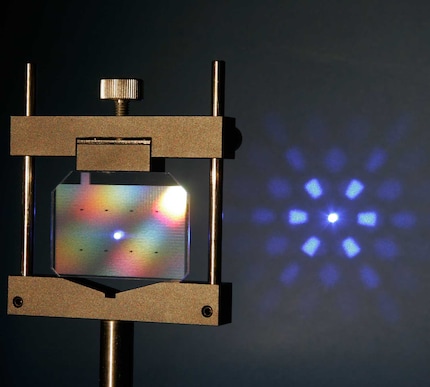

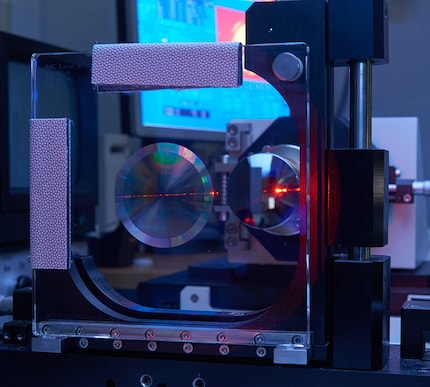

High precision solar cell scribing

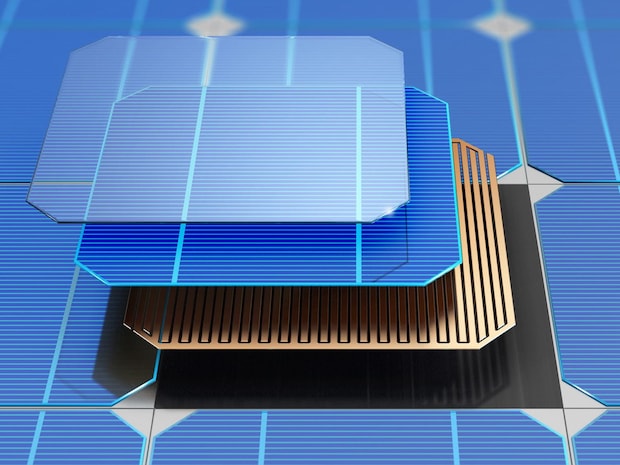

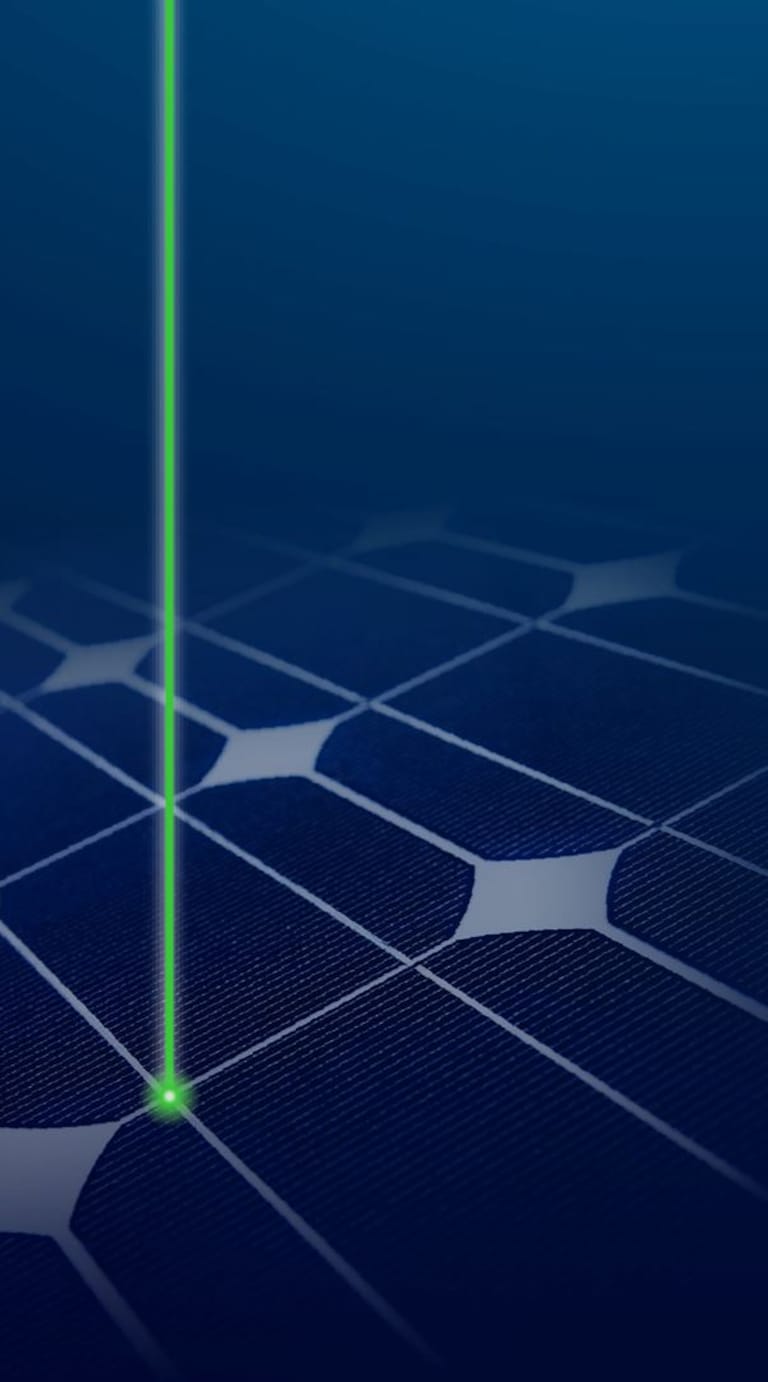

Laser processing plays a crucial role in the manufacturing of thin-film solar cells, particularly for scribing cell interconnects and isolating module edges. Advanced optical components, such as Jenoptik’s F-Theta lenses, facilitate the creation of finer, smaller, and denser patterns on solar cells. These lenses are vital for consistently achieving high-precision results in various tasks, including laser structuring, soldering, and welding. For many applications, the use of ultra-short pulse lasers is essential, and the F-Theta objective must be capable of maintaining performance over the long term.

Key considerations for high-end laser systems:

- Substrate protection: Ensuring the integrity of the substrate and underlying layers is essential, especially for sensitive structures under 100 nanometers.

- Quality management: Effectively managing particle residue, thermal effects, and edge burr formation is crucial for maintaining high-quality results.

- Optimized process parameters: Careful consideration of gas atmosphere, pulse shaping, and post-processing techniques enhances overall quality. Utilizing hybrid processes like thermochemical ablation can effectively address specific challenges in structuring materials such as Indium Tin Oxide (ITO).

Expand your limits and benefit from optimized F-Theta  features:

- Large scan fields

- Large focus lengths

- Excellent focus homogeneity over the entire field

- High beam stability

Discover the new application-tailored F-Theta lenses

JENar™ APTAline™ 429-515...540-339-AL

| Parameters | |

| Focal length | 429 mm |

| Wavelength | 515 - 540 nm |

| Scan field (X x Y); Ø | (240 mm x 240 mm); 339 mm |

| Diagonal scan angle | ± 22.8° |

| Back working distance | 547.7 mm |

| X/Y mirror angle | ± 8.0 |

| Flange focus distance | 629.5 mm |

| Input beam Ø 1/e² | 16.0 mm |

| Focus size Ø 1/e² | 26.9 µm |

| a1 | 17.00 mm |

| a2 | 32.51 mm |

| Telecentricity (only F-Theta | with scanner) | 12.4° | 12.4° |

| Group delay dispersion (GDD) | 3328 fs² |

| LIDT coating pulsed; CW | 1.25 J/cm² * (τ/[ns])0.35; 1.25 MW/cm² |

| LIDT system pulsed; CW | 1.25 J/cm² * (τ/[ns])0.35; 1.25 MW/cm² |

| Weight | 1.5 kg |

| Order number | 739668 |

JENar™ APTAline™ 420-355-353-AL

| Parameters | |

| Focal length | 420 mm |

| Wavelength | 355 nm |

| Scan field (X x Y); Ø | (250 mm x 250 mm); 353 mm |

| Diagonal scan angle | ± 24.0° |

| Back working distance | 496.0 mm |

| X/Y mirror angle | ± 8.5 |

| Flange focus distance | 572.0 mm |

| Input beam Ø 1/e² | 15.0 mm |

| Focus size Ø 1/e² | 18.9 µm |

| a1 | 17.00 mm |

| a2 | 35.1 mm |

| Telecentricity (only F-Theta | with scanner) | 14.7° | 14.7° |

| Group delay dispersion (GDD) | 6350 fs² |

| LIDT coating pulsed; CW | 0.5 J/cm² * (τ/[ns])0.4 ; 0.5 MW/cm² |

| LIDT system pulsed; CW | 0.5 J/cm² * (τ/[ns])0.4 ; 0.5 MW/cm² |

| Weight | 1.4 kg |

| Order number | 739569 |

Unlock the full potential of your processes in high-precision:

- Laser scribing

- Laser marking

- Laser doping

You have further questions? Contact our expert for optics and optical systems: