Design flexibility from the component to the sub-system level

- Laser Diodes & Epitaxy

- Open Heat Sink

- Diode Laser Stacks

- Fiber-coupled Modules

- Disk Lasers

- Sub-Systems

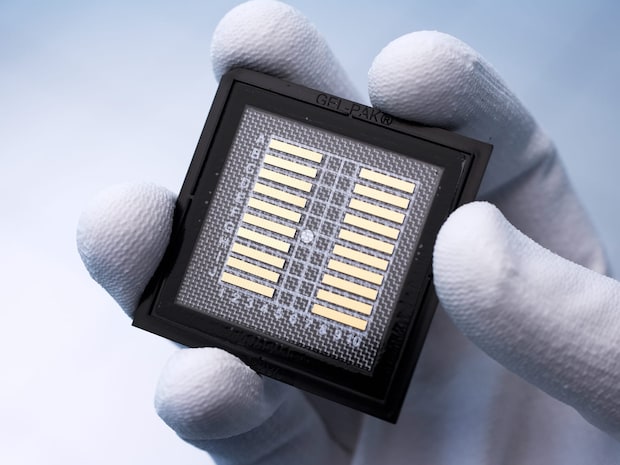

Unmounted high-power laser diodes

High-power laser bars for optical pumping and direct-diode-laser (DDL) applications in materials processing, medicine or sensing

Jenoptik has pioneered high-power diode laser technology and continues to provide industry-leading high-power broad-area edge-emitting diode lasers emitting in the 760 nm – 1060 nm spectral region.

We provide unmounted laser bars capable of operating in continuous-wave (cw), hard-pulse (hp)* long-pulse (lp)** and quasi-continuous-wave (qcw) up to 300 W (cw)/ 500 W (qcw) optical output power.

* hard-pulse refers to deep cycling from I = 0 to Imax @ e.g. on-times tON = 1 s and 50% duty cycle

** long-pulse refers to operation @ on-times tON ~ 5..100 ms and > 1% duty cycle

Epitaxial wafer services

Custom design epitaxial wafers for near-infrared (NIR) optoelectronic devices

Our epitaxial services address the need for Epi-wafer structures based on GaAs substrates and (Al, In, Ga) (As, P) compound semiconductors.We provide custom design epitaxial wafer structures for a variety of optoelectronic devices operating in the 630 nm – 1200 nm spectral range, for further wafer-level processing by our customers into, e.g.:

- Edge-emitting lasers: broad-area laser bars and single emitters

- Surface-emitting lasers: vertical (external) cavity surface-emitting lasers (VCSELs, VECSELs)

- Light-emitting diodes (LEDs): including superluminescent diodes (SLEDs) and resonant-cavity light-emitting diodes (RCLEDs)

- Photodetectors

What sets us apart

Our in-house epitaxy and wafer-level processing capability and in particular our flexibility to e.g.:

- Adjust the Epi-structure in order to

- fine tune the emission wavelength in accordance with the customer-specific packaging technology and the operating conditions to be applied

- provide the wavelength divisions required for dense-wavelength-beam-combining (DWBC) applications - Adjust the facet mirror, e.g. apply low anti-reflection (AR) coatings for applications requiring external feedback

- Apply facet passivation for highest optical output power levels

- Apply custom design metallization equally supporting In- and AuSn-based soldering

Product Offer

Laser Diodes

Correlating with the fill factor we distinguish three product groups for our 10 mm wide bars, each supporting particular applications and operating regimes:

- Low fill factor bars (typ. ≤ 30% fill factor) featuring low beam-parameter-product (BPP) suited for fiber coupling

- High-power bars (typ. 50% fill factor) for up to 300 W cw- and hard-pulse (hp) operation suited for optical pumping and direct-diode-laser (DDL) applications

- QCW bars (typ. FF > 65% fill factor): for up to 500 W qcw- and long-pulse (lp) operation suited for optical pumping and medical applications

For customers interested in broad-area single emitters, we selectively offer laser bars for cleaving into single emitters and qualification at customer site.

Epitaxial Wafers

Epitaxial wafers can be grown on 3’’, 4’’ or 6’’ GaAs-wafers depending on customer request using metal organic chemical vapor deposition (MOCVD)*.

*) alternatively known as: metal organic vapor phase epitaxy (MOVPE)

Ordering Information

Ordering Information

JDL-BAB-xx-xx-xxx-xx-xxx-x.xExample:

JDL-BAB-50-45-976-TE-200-4.0

- Fill Factor: 50%

- No. emitters: 45

- Wavelength*: 976 nm

- Polarization: TE

- Optical Power*: 200 W (cw)

- Resonator length: 4.0 mm

Technical Specifications

Emitters

Bars

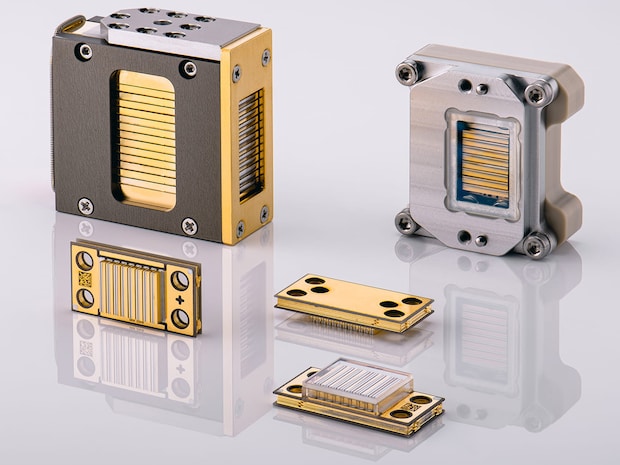

Open heat sink diode lasers: single-laser-bar packages based on passively- or actively cooled heat sinks

Leveraging our proprietary heat sink & assembly technology in order to provide mounted diode lasers with industry leading performance

Three figures of merit - optical output power - electro-optical (EO) efficiency – and package lifetime - characterize the performance of diode lasers operating at a desired emission wavelength and operating mode.

The most critical part in diode laser selection is not optical output power but optical output power at a well-defined reliability point required by the application.

Whether you focus on maximizing optical power at the expense of lifetime or maximizing lifetime at de-rated optical power conditions - we will support you in making the right product selection.

We at Jenoptik have pioneered high-power diode laser assembly in high-volume manufacturing and have been one of the first companies to introduce AuSn-soldering in the field.

While still applying industry standard heat sink designs (CS, CT) and established assembly technologies based on In- or AuSn-soldering, we at Jenoptik are mainly focusing on leveraging our proprietary, cutting-edge heat sinking and die attach technologies within our double-side passively cooled packages CN, LS and LK in order to serve most advanced optical pumping schemes and direct-diode-laser (DDL) technology. Close exchange between our in-house fab and our laser assembly site allow to tailor the laser bars employed towards the specific heat sink technology and the desired operating mode to be applied.

Optional beam collimation using microlenses or optional beam shaping using diffractive optical elements (DOE) round up our open heat sink laser technology portfolio in order to match your optical interface.

Featuring up to 300 W optical output power with our latest open heat sink generation LK

Benefit from our industry leading open heat sink diode laser product technology LK to translate increased power per mounted laser bar into reduced complexity and thus reduced cost of ownership on the system level – may your application be in optical pumping or DDL technology.

Optical output power levels up to 300 W in cw- and even hard-pulse mode can be reached in the 9xx nm region by combining Jenoptik's state-of-the art laser bars with our latest innovation in die-mounting and assembly technology.

Product Offer

Wide range of products and reliable cooling

- passively cooled heat sinks, i.e. single-bar packages which conductively spread and transfer dissipated power to a baseplate before waste heat is ultimately removed, e.g. via tap water cooling of the baseplate

- actively cooled heat sinks i.e. single-bar packages which are directly flooded e.g. with deionized water in order to convectively remove the heat directly from the heat sink

Active cooling allows for narrow heat sink designs which still make this heat sink technology an attractive building-block for densily packed horizontal arrays serving e.g. side-pumping applications.

Ordering Information

Ordering Information

JOLD-xxx-xxxN-1L-xxxExample and denotation of further options:

JOLD-180-CPFN-1L 940

- Optical Power*

180 W - Operating mode

C: cw

Q: qcw - Cooling

P: passive

A: active - Optics

N: none, free space

F: fast-axis

B: both, fast- and slow-axis - Wavelength*

940 nm

* Wavelength and optical output power @ desired operating conditions in accordance with the thermal impedance provided by the heat sink/ package.

Technical Specifications

Exemplary product selection shown.

Other wavelengths, heat sink variants, configurations upon request: please contact us for custom-design product variants.

| Output power in W | Operation mode | Cooling | Collimation | Heatsink | Data sheet |

|---|---|---|---|---|---|

| 55 | CW | passively cooled | fast axis | CS | JOLD-55-CPFN-1L |

| 60 | CW | passively cooled | without | CS | JOLD-60-CPNN-1L |

| 80 | CW | actively cooled | without | CT | JOLD-80-CANN-1L |

| 300 | QCW | passively cooled | without | CS | JOLD-300-QPNN-1L |

| 80 | CW | passively cooled | without | CS | JOLD-80-CPNN-1L |

| 180 | CW | passively cooled | Fast Axis | CN | JOLD-180-CPFN-1L |

| 200 | CW | passively cooled | without | CN | JOLD-200-CPNN-1L |

| 100 | CW | passively cooled | without | CS | JOLD-100-CPNN-1L |

| 160 | CW | passively cooled | without | CN | JOLD-160-CPNN-1L |

| xxx | CW | passively cooled | without | LK | JOLD-xxx-CPNN-1L |

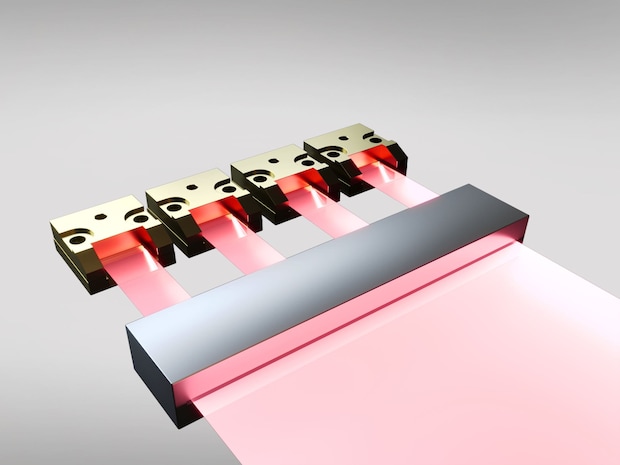

High-power diode laser stacks: actively- or passively cooled multi-laser-bar packages

Power scaling into the multikilowatt range for cw- and qcw-operation

Vertical stacking of individuals sub-mounts within multi-laser-bar packages offers a highly modular approach for power scaling well into the kW-range.

The modularity inherent in high-power diode laser arrays allows to flexibly scale-up a laser stack to the requested power level at a given center wavelength.

Vertical stacks are the diode laser package of choice for applications requiring primarily highest power levels.

Beam quality (beam-parameter-product, BPP) is optimized to the extent possible by applying lowest pitches (= distance between neighboring stacks) approaching 1,0 mm without compromising on cooling capacity of the submounts.

All our vertical stacks are tried & tested under application-specific conditions ranging from medical, industrial to mission-critical end use. Our proven hard-solder technology covers even the harshest environmental conditions.

Given the high modularity inherent in diode laser stack technology there is no one fits all solution.

Product Offer

Wide range of products and reliable cooling

QCW- and long-pulse operation are supported by our vertical stacks made up of CTE-matched submounts on Direct-Copper-Bonded (DCB) substrates. This type of vertical stack clearly offers several advantages:

- tap water or passive cooling of the DCB

- light-weight

- small footprint

- compact multi-stack arrangements offering additional power scaling - in integer numbers of stacks (multi-stack packages)

As an option, we additionally offer custom design multi-wavelength qcw-stacks for “color-mixing”.

CW-operation is supported by our microchannel-cooled packages (MCCP) which are actively cooled with deionized (DI) water. Best known-practices have been established with regard to microchannel designs, DI-water specification and cooling circuit maintenance in order to enable package-limited lifetimes in excess of 10.000 hrs - relevant for industrial applications.

Ordering Information

Ordering Information

JOLD-xxx-xxxn-xA-xxx

Example and denotation of further options:

JOLD-1200-CANN-12A-940

- Optical Power*

1200 W - Operating mode

C: cw

Q: qcw - Cooling

P: passive

A: active - Optics

N: none, free space

F: fast-axis

B: both, fast- and slow-axis - Housing

N: no housing

H: housed

W: protective window - No. of submounts

12 - Wavelength*

940 nm

*Wavelength and optical output power @ desired operating conditions in accordance with the thermal impedance provided by the the heat sink/ package.

Technical Specifications

Exemplary product selection shown.

Other wavelengths, heat sink variants, configurations upon request: please contact us for custom-design product variants.

| Wavelength in nm | Output power in W | Operation mode | Cooling | Collimation | Data sheet |

|---|---|---|---|---|---|

| 808 | 1560 | QCW | passively cooled | fast axis | JOLD-1560-QAF-2x8A-med |

| 808 | 1600 | QCW | passively cooled | without | JOLD-1600-QA-2x8A-med |

| 808 | 2160 | QCW | passively cooled | without | JOLD-2160-QF-8A |

| 808 | 2400 | QCW | passively cooled | without | JOLD-2400-Q-8A |

| 808 | 2400 | QCW | passively cooled | without | JOLD-2400-QA-8A-industry |

| 940 | 2160 | QCW | passively cooled | without | JOLD-2160-QF-8A |

| 940 | 2400 | QCW | passively cooled | without | JOLD-2400-Q-8A |

| 940 | 2400 | QCW | passively cooled | without | JOLD-2400-QA-8A-industry |

| 808 | 360 | CW | actively cooled | fast axis | JOLD-360-CAFN-8A |

| 808 | 400 | CW | actively cooled | without | JOLD-400-CANN-8A |

| 808 | 576 | CW | actively cooled | fast axis | JOLD-576-CAFN-8A |

| 808 | 600 | CW | actively cooled | without | JOLD-600-CANN-12A |

| 808 | 640 | CW | actively cooled | without | JOLD-640-CANN-8A |

| 808 | 800 | CW | actively cooled | without | JOLD-800-CANN-10A |

| 808 | 960 | CW | actively cooled | without | JOLD-960-CANN-12A |

| 940 | 440 | CW | actively cooled | fast axis | JOLD-440-CAFN-4A |

| 940 | 480 | CW | actively cooled | without | JOLD-480-CANN-4A |

| 940 | 660 | CW | actively cooled | fast axis | JOLD-660-CAFN-6A |

| 940 | 720 | CW | actively cooled | without | JOLD-720-CANN-6A |

| 940 | 1080 | CW | actively cooled | fast axis | JOLD-1080-CAFN-12A |

| 940 | 1200 | CW | actively cooled | without | JOLD-1200-CANN-12A |

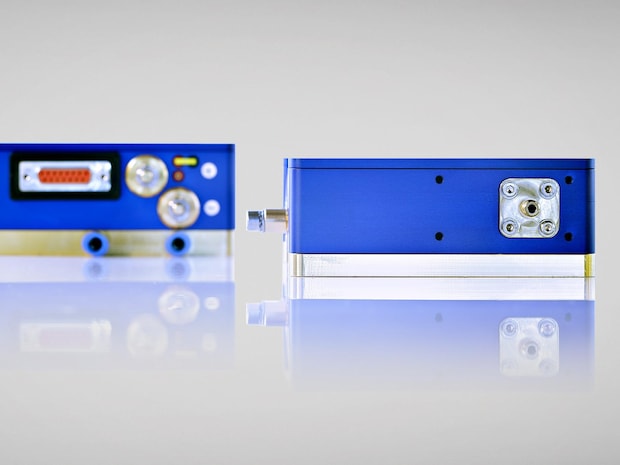

Fiber-coupled diode laser modules

Our legacy products: single- or multi-laser-bar fiber coupled modules in a rugged OEM design

The advent and fast growth of fiber lasers has lead many diode laser manufacturers to apply single-emitters as the basic building-block for power scaling in fiber-coupled modules, since they enable coupling at high beam quality into 105 µm / NA 0.15 fibers as required for current fiber laser pumping schemes.

The bulk of our fiber-coupled diode laser modules are

- passively cooled: i.e. the module is mounted on e.g. tap-water cooled baseplate via thermally conductive foil

- compatible with 200/ 400 µm core/ NA 0.22 fibers

- operating up to 100W cw @ 808 and up to 150 W cw @ 940, 980 nm

The use of monolithic multi-emitter laser bars as well as monolithic optics (beam-twisters) make bar-based fiber coupled modules the most cost-effective solution for low-brightness DDL applications.

Technical Specifications

Exemplary product selection shown.

Other wavelengths, heat sink variants, configurations upon request: please contact us for custom-design product variants.

| Wavelength in nm | Output power in W | Operation mode | Cooling | Fiber core diameter in mm | Data sheet |

|---|---|---|---|---|---|

| 808 | 30 | CW | passively cooled | 0.2 | JOLD-30-FC-12 |

| 808 | 30 | CW | passively cooled | 0.4 | JOLD-30-FC-14 |

| 808 | 30 | CW | passively cooled with TEC | 0.4 | JOLD-30-CPXF-1L |

| 808 | 45 | CW | passively cooled with TEC | 0.4 | JOLD-45-CPXF-1L |

| 808 | 70 | QCW | passively cooled with TEC | 0.6 | JOLD-70-QPXF-1L |

| 808 | 120 | QCW | passively cooled with TEC | 0.6 | JOLD-120-QPXF-2P iTEC |

| 808 | 140 | CW | aktively cooled | 0.6 | JOLD-140-CAXF-6A |

| 808 | 210 | CW | aktively cooled | 0.6 | JOLD-210-CAXF-6A |

| 915 | 400 | CW | aktively cooled | 0.6 | JOLD-400-CAXF-6P2 |

| 940 | 45 | CW | passively cooled with TEC | 0.4 | JOLD-45-CPXF-1L |

| 940 | 75 | CW | passively cooled with TEC | 0.4 | JOLD-75-CPXF-2P iTEC |

| 940 | 140 | CW | aktively cooled | 0.6 | JOLD-140-CAXF-6A |

| 940 | 210 | CW | aktively cooled | 0.6 | JOLD-210-CAXF-6A |

| 980 | 75 | CW | passively cooled with TEC | 0.4 | JOLD-75-CPXF-1L |

| 1470 | 20 | CW | passively cooled | 0.4 | JOLD-20-FCM-14 |

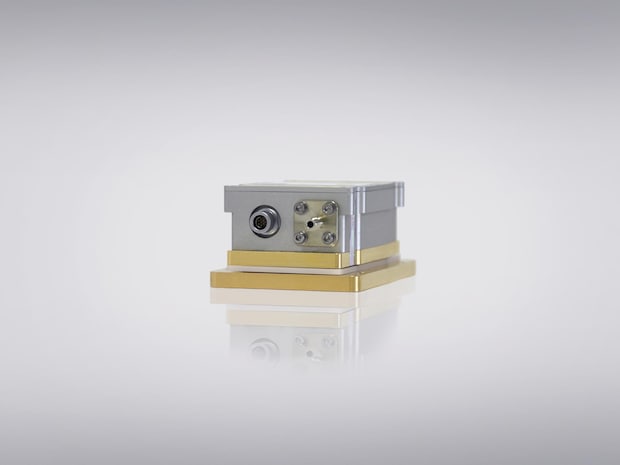

Frequency-doubled diode-pumped disk lasers

Our trusted 532 nm laser sources with up to 8W continuous-wave output power for proven applications in medicine, illumination and signaling

Jenoptik has pioneered development and commercialization of diode-pumped thin disk laser technology and has over 30 years experience in the design and fabrication of diode-pumped solid state lasers.

With more than 25.000 units installed, our cw-532 nm thin disk lasers are proven in the field for a variety of applications such as ophthalmology, dermatology, veterinary medicine, laser projection and quality control.

Operation of our 532 nm thin disk lasers relies on TEC-controlled laser diode pump sources from our in house-fab, Nd:YVO4 gain crystals and TEC-controlled internal frequency doubling LBO crystals.

Compared to other solid-state laser technologies, thin disk lasers offer highest electro-optical efficiency, water-less cooling of the gain medium and high beam quality (M² ~ 5) due to suppression of thermal lensing. This enables us to serve applications in the medical field of laser-based-therapy with our proven and highly reliable JenLas® D2.x and JenLas® D2.mini series.

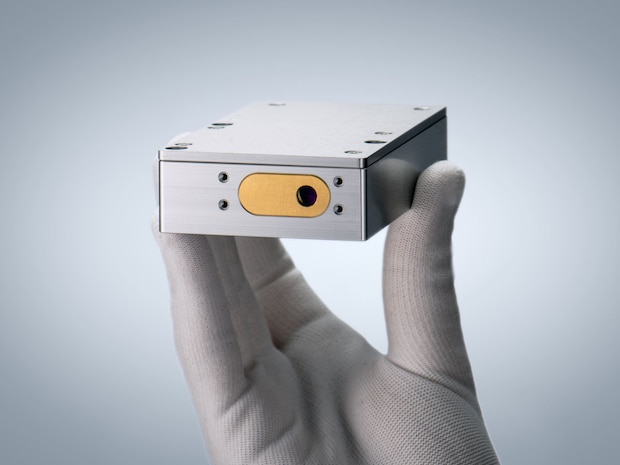

The miniaturized JenLas® D2.mini 2-8W with its industry-leading, lowest form-factor fits into the palm of your hand and exhibits a rugged, sealed OEM-design for easy integration into your medical laser system.

Product Offer

Three levels of integration are available:

- JenLas® D2.mini 2-8W free-space

- JenLas® D2.mini 3/8 W FC: fiber coupling into 100 µm core, NA = 0.11 (standard))

- JenLas® MLS Green: fully integrated, i.e. including fiber-coupling, control electronics, cooling and functional safety features conforming with the IEC 60601 medical electrical equipment norm

Technical Specifications

Data Sheet JenLas® D2.mini

Laser sub-systems: tailored solutions for customer specific applications

Leveraging our in-house expertise in laser technology and system integration in order to provide highly customized laser-based solutions

Open heat sink high-power diode lasers present a highly versatile building-block for modular scaling and configuring customized diode laser systems.

Next to providing the diode laser component as a building-block, we combine and leverage

- our overall expertise in laser system integration

- our expertise in thermo-mechanical design

- our partner network for laser control and safety electronics

- our knowledge of the normative landscapes, e.g. for medical electrical equipment

- our project manager pool

in order to co-develop highly customized laser systems tailored to your needs. While primarily focusing on diode laser based solutions, e.g.

- Diode laser assemblies, e.g. linear laser source assemblies for low-brightness, line laser applications in materials processing, e.g. welding, heating, curing or annealing

- Fiber-coupled diode laser systems, e.g used for laser-based etching in the semiconductor industry

We are also intetgrating:

- Solid-state lasers, as in our medical laser system JenLas® MLS Green

- Fiber lasers: e.g. based on our JenLas® fiber ns 25 – 105 for high precision applications in industrial marking and micromachining

Product Offer

JenLas®MLS Green

Highest precision in eye treatment thanks to reliable medical laser solutions.

Applications

JenLas®MLS Green is a class 4 OEM laser source for

- Retinal photocoagulation

- Trabeculoplasty

- Iridotomy

Features

- Certified as medical electrical equipment

- Aiming beam

- Fiber-coupling

- Short pulse duration

- Precise energy control

- Enabling short treatment times

Nanosecond fiber laser JenLas® fiber ns 25 - 105

Label, mark, and structure a variety of materials with extreme precision using nanosecond lasers.

The JenLas® fiber ns 25-105 laser product family opens up a wealth of possibilities for laser material processing applications: the pulsed nanosecond fiber lasers are suitable for labeling, marking, and cutting different materials, as well as for structuring your surface exactly. They create laser marks on metals or plastics, for example, while extremely thin layers can be removed precisely.

Applications

JenLas® fiber ns is a class 4 OEM laser source for

- Marking and scribing of metals, plastics, ceramics

- Laser cleaning of surfaces

- Generation of surface structures

- Trimming of resistors and PCB traces

- Cutting and drilling of thin foils

- Thin film ablation from transparent substrates

Features

- Scalable power level from 20W to 100W

- Rugged industry-proved fiber laser technology

- Enhanced robustness against backreflection

- Designed for integration into industrial machines

- Complete control by software, hardwired or mixed

- Add-on parts from collimation optics up to complex optical solutions

- On-axis guiding laser

Your benefits

- Custom design:

Customized laser solutions for your specific application. - Design flexibility:

We are able to respond flexibly to your requirements. - Cost effective solutions:

Reduced cost of ownership through reliable laser solutions. - Highest quality:

We strictly monitor the production in clearly defined processes based on certifications.

Fields of applications

- Medicine:

Laser based therapy for ophthalmlogy, dermatology and esthetics - Material processing / Direct diode laser application:

Welding, soldering, hardening and annealing - Optical pumping:

Solid state lasers (Nd:Yxx, Yb:xx, etc.) - Others:

Metrology, sensing, printing, laser projection, etc.

Make use of our laser product portfolio to configure and co-develop with us the laser solution you need.

Do you have any questions? Our experts are happy to help.